Disclaimer: this article was originally published by Shantui Shares.

Sources: https://mp.weixin.qq.com/s/dbcpjqykO4Z__xReQ8s8ug

As temperatures continue to rise, the frequency of air conditioner use is gradually increasing. The main points for the use and daily inspection and maintenance of the excavator air conditioning system include the following aspects:

Points of Attention for Use

- Starting sequence (compressor start-up):1) It is not recommended to immediately turn on the air conditioning before starting the engine. It should be started after the engine has been started and is running stably, to reduce the additional burden on the engine during the air conditioning start-up. 2) Run the air conditioning at idle speed regularly (weekly) to circulate the oil in the air conditioning system and prevent the compressor from seizing due to lack of oil.

- Temperature setting:When setting the air conditioning temperature, it should be set reasonably according to the actual needs and external environment. Avoid setting the temperature too low to reduce engine load and fuel consumption.

- Air blowing mode selection:Choose the appropriate air blowing mode according to actual needs, such as blowing at the face, feet, or windshield. In winter, foot-blowing mode can be selected to increase the temperature of the cabin; in summer, face-blowing mode can be selected for better cooling effects.

- Switching between internal and external circulation:In environments with poor air quality or heavy dust, it is recommended to use the internal circulation mode to reduce the impact of external air on the inside of the cabin. However, after using internal circulation for a long time, it should be switched to external circulation mode appropriately to ensure air circulation inside the cabin.

Points of Attention for Daily Inspection and Maintenance

- Checking the refrigerant level

- Inspection content: Use a manifold pressure gauge to ensure sufficient refrigerant in the system, and if there is an obvious lack of refrigerant, first confirm and find if there is a leak in the system, and do not blindly add refrigerant.

- Problems that may occur if not checked properly: Insufficient refrigerant can lead to poor refrigeration and wear and seizure of the compressor due to insufficient oil return.

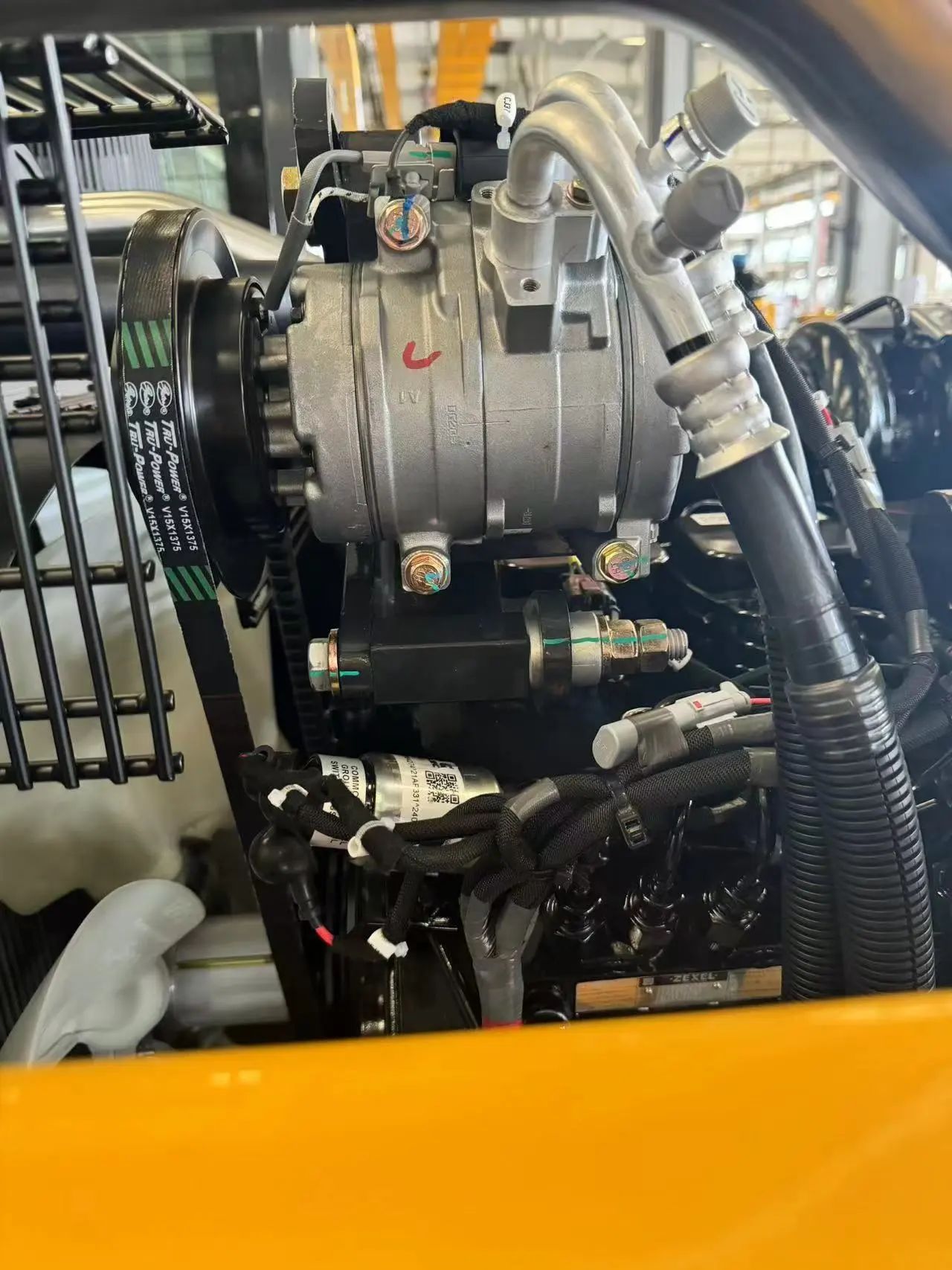

- Checking the compressor clutch area

- Inspection content: Confirm if the compressor’s wiring harness connections are normal, and the clutch area should not have mud, soil, or other deposits; if there is any, clean it promptly.

- Problems that may occur if not checked properly: Poor wiring harness connections can cause the compressor to stop working, and dirt deposits can cause wear to the clutch-related parts and the main shaft seal.

- Checking the inner/outer air filters

- Inspection content: Check and confirm the cleanliness of the inner/outer air filters, and clean or replace filters that are dusty or unclean in a timely manner.

- Problems that may occur if not checked properly: This can lead to reduced airflow or dust accumulation causing filter deformation and dust intrusion into the evaporator, leading to blockage of the evaporator. It also affects the user’s health.

- Checking the condenser core

- Inspection content: Check and confirm the cleanliness of the condenser core, and clean it promptly if there is a lot of dust or foreign matter attached.

- Problems that may occur if not checked properly: Foreign matter attached to the core for a long time can lead to corrosion and leaks, as well as poor heat dissipation due to blockage of the core, which increases the system pressure and results in poor refrigeration.

- Implementing initial idle operation

- Inspection content: When the air conditioning refrigeration is not used for a long time, and when it is used again, it must be started while the engine is idling and kept running for more than 5 minutes before accelerating. For vehicles that have not been used for more than 7 days, the same procedure should be followed when restarting.

- Problems that may occur if not checked properly: This can lead to insufficient fusion of refrigerant and compressor oil, and in high-speed conditions, the compressor oil is rapidly pressed out and cannot effectively return to the compressor, causing the compressor to seize due to lack of oil.

In summary: For the use of the excavator air conditioning system and daily inspection and maintenance, attention should be paid to the above aspects. Only through correct usage and regular inspection and maintenance can the normal operation of the air conditioning system be ensured, thereby improving the service life and efficiency of the excavator.

Keywords: