Against the backdrop of growing global infrastructure construction demand and rising labor costs, the construction machinery industry is undergoing a profound transformation driven by digitalization, automation and intelligent technologies.

Marriage between construction machinery giants and technology companies: an intelligent revolution in the field of mechanical control

Recently, three major collaborations, including Volvo Construction Equipment and UniControl, Kobelco Construction Machinery and Leica Geosystems and Xwatch, and Caterpillar and technology companies, have introduced LiDAR technology into a new generation of autonomous machinery, revealing the accelerating trend of technology integration in the industry. These cross-border collaborations will not only redefine the operation mode and efficiency standards of construction machinery, but will also have a profound impact on the operation mode and management concept of future construction sites.

Cross-border cooperation has become the new normal in the industry: complementary advantages solve application problems.

The construction machinery industry is facing unprecedented transformation pressure. On the one hand, the global construction industry faces a shortage of skilled operators. According to statistics from the American Association of Builders, the labor shortage in the US construction industry will reach 650,000 in 2022.

On the other hand, the requirements for precision, efficiency and safety of engineering projects are constantly increasing, and traditional machinery can no longer meet these requirements.Against this background, the strategic cooperation between construction machinery manufacturers and technology companies has changed from “optional” to “mandatory”.

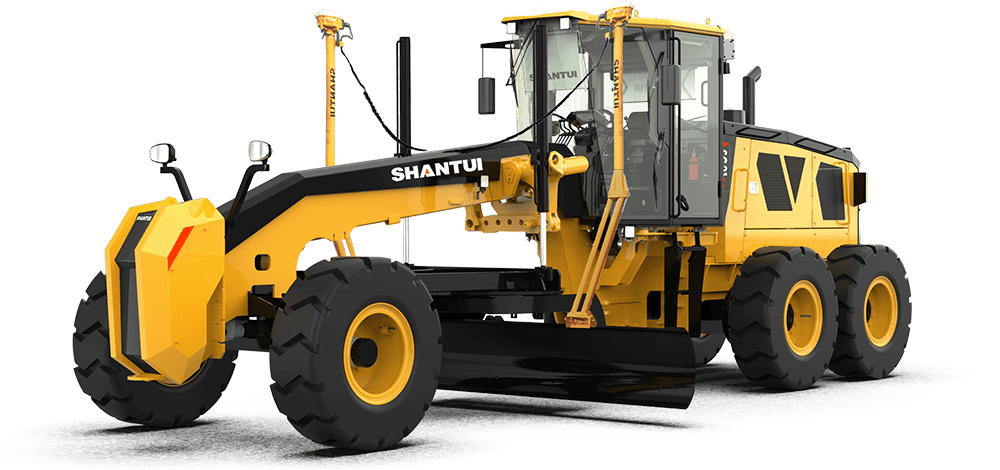

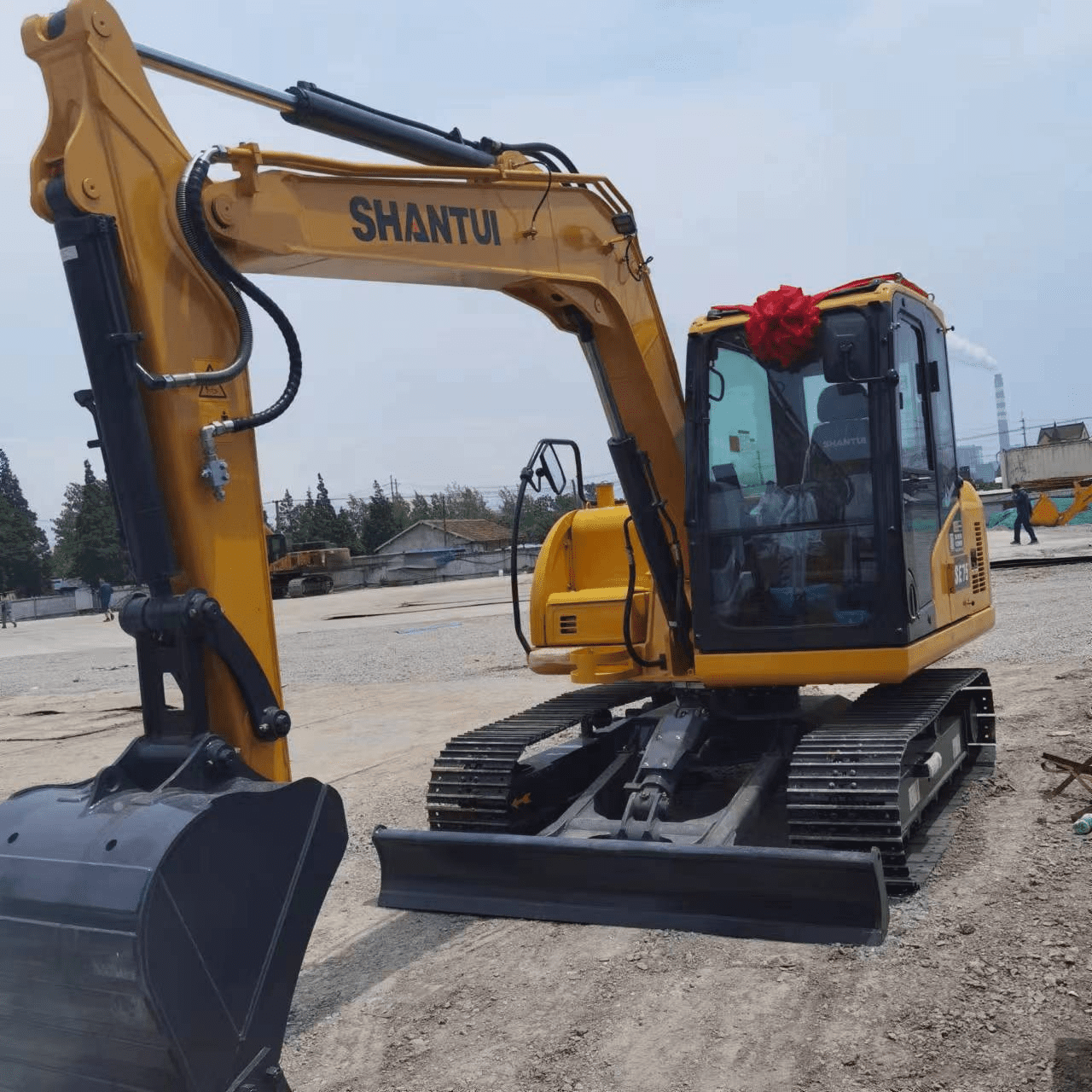

The cooperation between Volvo Construction Equipment and UniControl represents a classic combination of machinery manufacturers and control software experts. Although UniControl, founded in Poland, is not large in scale, the universal machine control technology it has developed has solved the long-standing pain point in the industry – the incompatibility of control systems between machines of different brands and models.

Through this cooperation, Volvo CE can provide “plug-and-play” control solutions for its full range of equipment. Customers no longer need to equip each device with a dedicated control system, which greatly reduces the cost of digital transformation.

This cooperation model shows that the machinery giant is shifting from a “closed system” mentality to an “open platform” strategy, and quickly filling its own shortcomings in specific technical fields through cooperation with professional technology companies.

Sales in the North American market fell by 5% last year, a shallower-than-expected decline. Although the local construction market remains strong, three consecutive years of record sales from 2021 to 2023 have led to saturation of equipment inventory.

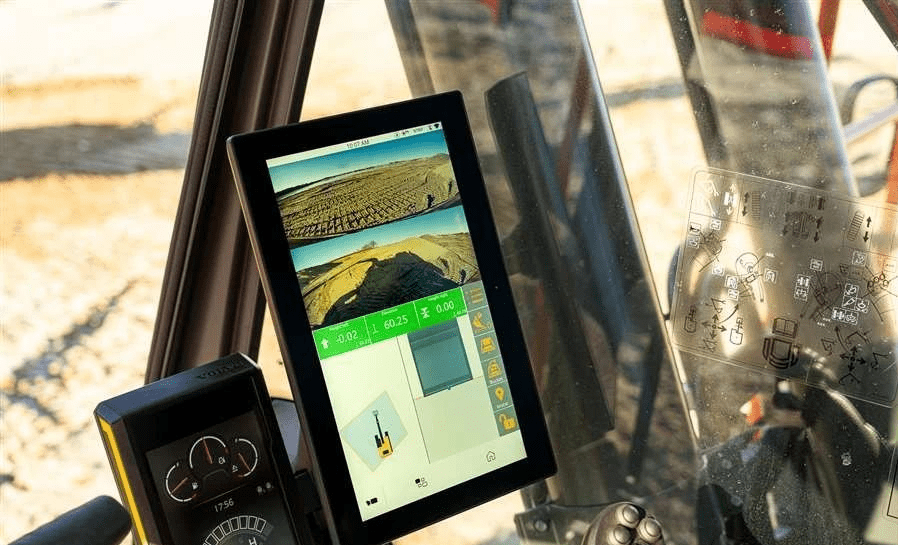

Kobelco Construction Machinery’s three-way cooperation with Leica Geosystems and Xwatch is more complex, integrating geospatial measurement technology with remote monitoring solutions. The high-precision GNSS (Global Navigation Satellite System) and total station technology brought by Leica Geosystems, combined with Xwatch’s remote monitoring platform, enables Kobelco’s machinery and equipment to simultaneously obtain the two major capabilities of “spatial perception” and “status visualization”.

This “1+1>2” technical synergy effect is exactly what a single company cannot achieve independently. It is particularly noteworthy that the cooperation pays special attention to the development of “remote technology”, pointing directly to the urgent need of the global construction industry to reduce on-site personnel and enhance remote collaboration after the epidemic. Caterpillar’s cooperation with an unnamed technology company (presumably Aeva or Luminar, a LiDAR emerging company based on industry information) focuses on the “eyes” of the next generation of autonomous machinery – LiDAR (laser radar) technology. Unlike the first two cases, which mainly aim to improve the digital level of existing machinery, this cooperation is more forward-looking and aims to lay the foundation for perception of fully autonomous construction machinery. LiDAR can create high-precision three-dimensional environmental maps and is the core sensor for autonomous vehicles to understand the surrounding environment. Carter chose to cooperate with professional LiDAR companies rather than traditional parts suppliers, reflecting that the degree of reliance on cutting-edge perception technology in the development of autonomous machinery has exceeded the technical accumulation of traditional machinery manufacturers.

Although the three cooperations have different focuses, they jointly reveal an industry trend: the intelligent upgrade of construction machinery can no longer rely on the linear technology improvement of a single enterprise, but requires the construction of a cross-industry technology ecosystem.

Machinery manufacturers provide equipment platforms and industry know-how, and technology companies contribute special technologies. Both parties jointly overcome the “last mile” application difficulties from laboratory to construction site.

As Volvo CE’s technical director said in an interview: “No company can monopolize all good ideas. The future belongs to those companies that are best at cooperation.”

Technology integration reshapes the construction paradigm: from single-machine intelligence to system collaboration

Analyzing the specific technical directions involved in these three cooperations, we can clearly see the three key dimensions of the intelligent development of construction machinery: machine control standardization, remote operation process and equipment autonomy. These technologies not only have revolutionary potential, but will also produce stronger synergies in integration. The machine control standardization promoted by Volvo and UniControl seems to be just the unification of software interfaces, but in fact it will change the technical ecology of the entire construction site. In the traditional model, machines of different brands or even different models need to use their own control systems, operators need to learn multiple interfaces, and it is difficult for site managers to integrate data.

UniControl’s universal platform is like the “Android system” in the construction machinery industry, enabling different devices to “speak the same language”. This standardization not only reduces the complexity of operation, but more importantly, lays the foundation for the collaborative operation of the equipment group on the site. When the data of excavators, loaders, and bulldozers can flow seamlessly, a true “digital site” becomes possible. According to Volvo’s calculations, the use of a unified control system can reduce equipment setup time by 40% and reduce the cost of digital transformation of the entire project by 25-30%.

The remote technology of the cooperation with Kobelco directly hits the two major pain points of the current construction industry: safety and talent shortage. Leica Geosystems’ intelligent total station can monitor the position and operation accuracy of machinery in real time, and Xwatch’s solution enables engineers to remotely diagnose the status of equipment and even make some operational adjustments.

This means that an experienced operation expert can guide operations at multiple construction sites at the same time, or remotely control equipment in dangerous areas that are not suitable for personnel to enter (such as nuclear power plant demolition and disaster rescue).

Test data disclosed by Kobelco shows that after adopting remote monitoring, the average discovery time of equipment abnormalities has been shortened from 4.2 hours to 0.5 hours, and the maintenance response speed has increased by more than 80%.

It is worth noting that this remote capability forms a virtuous circle with the popularization of 5G networks – faster network speeds make higher-precision remote operations possible, and the needs of the construction industry have promoted the application of 5G in industrial scenarios.

The LiDAR and autonomous machinery explored by Caterpillar represent the ultimate vision of the industry – an intelligent construction system that does not require any human intervention.

The advantage of LiDAR over traditional cameras or radars is that it is not affected by lighting conditions and can directly obtain three-dimensional spatial information with an accuracy of up to centimeters.

This perception capability is crucial for equipment such as Crawler bulldozer and excavators that require precise earthwork operations. Caterpillar has previously successfully deployed autonomous transportation systems in the field of mining trucks, but the combination with LiDAR technology will push autonomy to more complex construction scenarios.

According to people familiar with the matter, Carter’s new system can automatically identify the best operating path in complex terrain and adjust the bucket movement according to the real-time earthwork volume. Its operating efficiency is close to 90% of the level of skilled operators. Although it will take some time for fully autonomous construction machinery to be commercialized on a large scale, this technical direction will undoubtedly redefine the connotation of “construction efficiency”.

In-depth analysis of these technical directions shows a common feature: they are all promoting the evolution of construction machinery from “single machine intelligence” to “system intelligence”. Standardized control is the basis for dialogue between equipment, remote technology is a new way for people to interact with the system, and autonomy is the ability of the system to make self-decision. The construction site of the future will no longer be a simple collection of machinery, but an intelligent organism that can self-coordinate and self-optimize. This transformation requires not only technological innovation, but also a comprehensive reconstruction of traditional construction processes and management models.

Standardized control is the basis for dialogue between equipment, remote technology is a new way for people to interact with the system, and autonomy is the ability of the system to make self-decision.

The construction site of the future will no longer be a simple collection of machinery, but an intelligent organism that can self-coordinate and self-optimize. This transformation requires not only technological innovation, but also a comprehensive reconstruction of traditional construction processes and management models.

Keywords: