Disclaimer: The material in this article comes from reports by foreign media websites, compiled and translated by the Machinery Intelligence Station AI. The views in the article do not represent this site. Contributions, shares, and conversations are welcome.

This article shares a blog post from the “Construction Machinery and Transportation” channel, a well-established Russian social media platform.

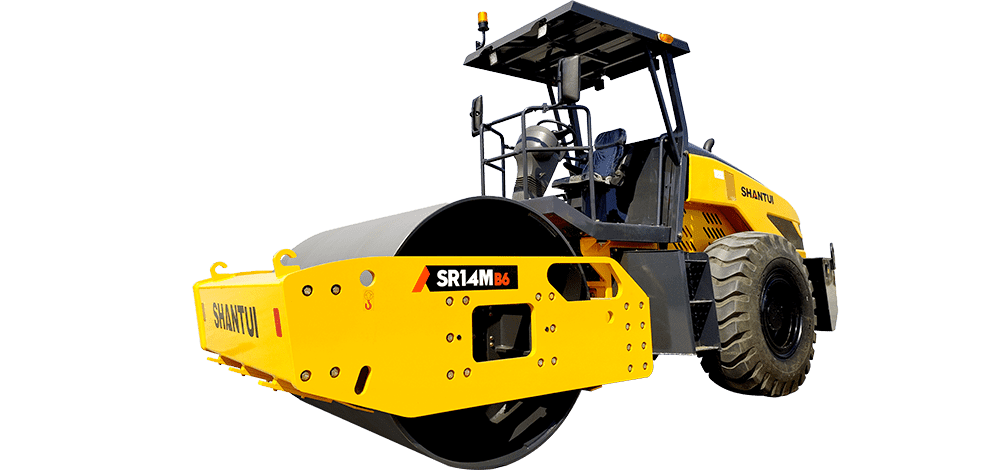

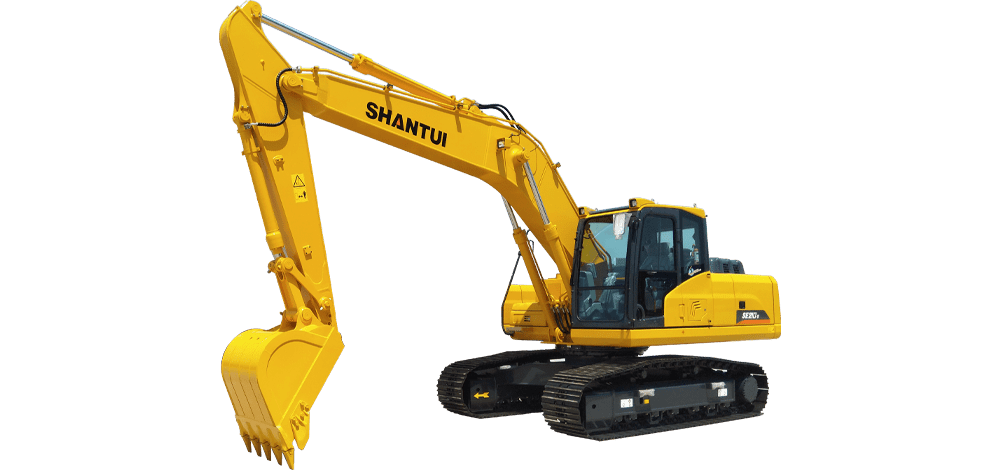

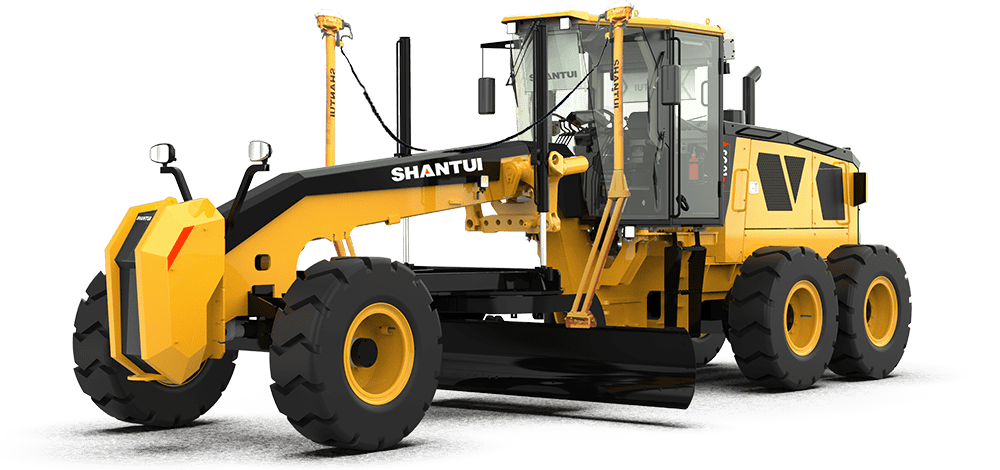

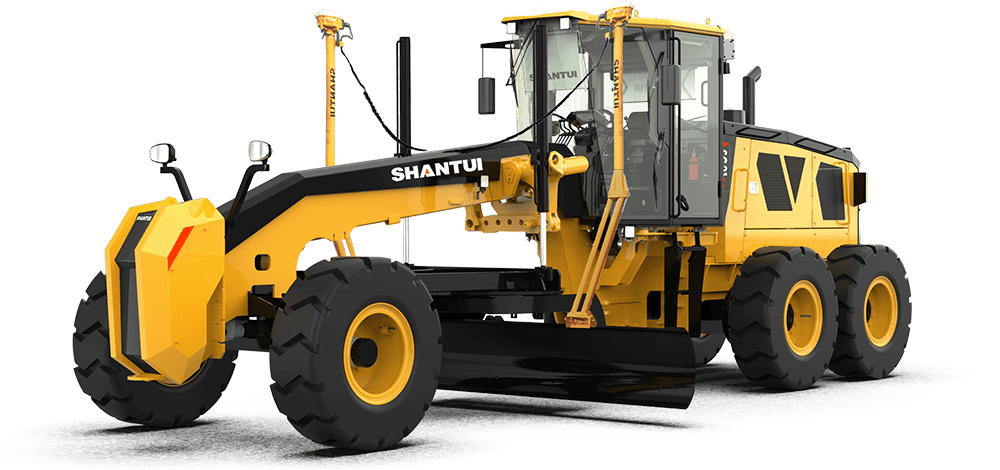

The “Construction Machinery and Transportation” channel has been continuously monitoring the production situation of Russian engineering machinery and openly reporting to its readers about everything that is happening. The channel analyzed production statistics for major types of engineering machinery in the first half of 2024, and the results are as follows: Compared to the already pessimistic data from 2023, this year’s production outcomes for many machines are even more disappointing. To get an idea of last year’s situation, here are some statistics. By the end of 2023, the market share of local manufacturers in the Russian market was as follows: excavators (excluding small and mining excavators) 5%, loaders 5%, backhoe loaders 3%, road rollers 10%, mini skid steer loaders 13%, bulldozers 25%, motor graders 35%, and wheel cranes 45%. The majority of other machinery came from China. Additionally, Russia also received some equipment from Korea and machinery from countries considered unfriendly.

Since February 2022, the production of truck cranes had been in decline.

Because of a severe shortage in automotive chassis, which were first prioritized for the front lines, crane factories are struggling to survive under these tough circumstances. Additionally, as the special military operation continues, the situation has reached a critical stage due to labor shortages. This, along with the Russian Central Bank’s tight credit policy, has dealt a significant blow to the real economy. Moreover, our Chinese friends introduced a large amount of machinery at the end of 2023 and continued to dump them on the market in the first half of 2024. Clearly, all these factors are affecting not just the production of truck cranes.

The main chassis for Russian crane manufacturers is KAMAZ. Such chassis are used in more than 80% of automotive cranes, with about 80% of these being all-wheel drive KAMAZ trucks. However, in the first half of 2024, the supply of KAMAZ chassis dropped by 30% in comparison to the same period in 2023.

In this situation, producers of truck cranes have not been proactive in replacing the national chassis with Chinese ones. It is understood that the Galich and Klintsovsky crane factories as well as the Kamyshin crane factory have only modestly utilized chassis supplied by Chinese customers. Meanwhile, the Chelyabinsk machinery factory mastered the independent assembly technology for 6×6 hub chassis of complete vehicles from China’s Beiben Trucks factory this year. ChMZ is installing cranes with lifting capacities of 25-32 tons on these chassis.

According to the analysis company Avtoselkhozmashholding, Avtokran from the Ivanovo machinery factory showed the largest drop in production in the first half of 2024, assembling 184 truck cranes, a 25% decrease from the same period in 2023.

From January to June 2024, Russia’s largest crane manufacturing holding company Kudesnik decreased its production of automotive cranes by 22% year-on-year, from 657 units in the same period last year. Among the holdings’ three enterprises, the Klintsovsky and Galichsky crane factories remained level, both at 294 units, marking a 20% decrease. Kamyshin crane factory produced 69 cranes, a 35% drop year-on-year.

During the reporting period, the Chelyabinsk machine factory produced 263 truck cranes, a 15% reduction compared to the same period in 2023. ChMP stated that despite the downturn in production of their main product, the focus has shifted towards a diversification of production, expanding the manufacturing of 16 to 40-tonne crawler traction cranes and developing an entirely new 9-tonne crane.

Additionally, a small number of crawler cranes were also produced in the first half of 2024: ChMP produced 6 units, one less than last year; KAZ produced 2 units, maintaining last year’s output.

In Russia, the only enterprise still producing tower cranes is the Casting and Mechanical Factory in the city of Nyazepetrovsk. In the first half of 2024, the factory produced 32 GIRAFFE cranes, an increase of 2.2 times over the same period last year.

The situation with the production of full-revolving excavators varies from plant to plant.

Tverskoy Excavator Plant, part of the UMG Group, produced 241 excavators (excluding backhoe loaders) in the first half of 2024, a 14% increase year-on-year. The Eksmash plant assembled 151 excavators, a 13% decrease compared to last year.

Kranex’s Ivanovo plant produced 24 excavators at its old site in Ivanovo, almost a fivefold increase year-on-year, and 20 at its new plant in Yaroslavl, a 63% decrease compared to the same period. It is worth mentioning that since the end of 2022, Kranex announced the launch of modern series excavators jointly produced with a Chinese partner. It is also noteworthy that the Ivanovo workers are now producing these excavators not only under their own brand but also for new Russian partners under the “CHETRA” and “DST-Ural” brands.

Here’s the production situation for backhoe loaders.

The Tver excavator factory fully restored the production of backhoe loaders in the first half of 2024. This production line had been halted since February 2022 due to an interruption in imported components. During the reporting period, a total of 121 backhoe loaders were assembled, compared to only 6 during the same period last year.

ELAZ increased its output by 65%, assembling 132 backhoe loaders.

Cheboksary Casting and Mechanical Plant produced only 36 backhoe loaders, a 42% decrease from the previous year. This year, the plant produced only machines based on Belarusian tractors and did not produce backhoe loaders based on specialized chassis from Belarusian Dorelektromash.

Next is the production of loaders.

The Amkodor-Bryansk plant, which used to be the top manufacturer of such equipment, saw a 70% drop in production in the first half of 2024, producing only 38 loaders.

Chelyabinsk ChSDM factory (part of the UMG Group) began a joint project with a Chinese factory to localize loader production last year. Over the past six months, the factory produced a total of 81 loaders, a 33% decrease from last year.

The St. Petersburg tractor factory produced 44 loaders in the first half of 2024, a 15% decrease year-on-year.

DST-Ural, which specializes in industrial tractors, developed new models in recent years, including wheel loaders. A total of 34 were produced in the first half of 2024 compared to just one last year.

Rybinsk Road Machinery Plant produced 3 loaders during the reporting period compared to 13 last year.

Production of mini skid steer loaders also varied.

Kovrov Electromechanical Plant (part of the state-owned Rostec’s Precision Systems Holding Company) produced 166 mini skid steer loaders in the first half of 2024, down 37% year-on-year. It should be noted that the metal structures for these mini skid steer loaders were manufactured by Rybinsk Raskat Factory, which is also part of the “Precision Systems” Holding Company.

CHETRA MKSM mini loaders are produced at the SAREX factory in Saransk (now an independent structural division of the Cheboksary factory “Promtractor”), with a total of 165 units manufactured in the first half of 2024, an 8% increase over the same period in 2023.

Kurganmashzavod, previously one of the largest mini skid steer loader (MKSM brand) manufacturers, has stopped producing such loaders since 2023 due to increased defense orders.

Another manufacturer from Kurgan, the Kurgandormash factory, is a newcomer to the mini skid steer loader market. In the first half of 2024, 41 pieces of equipment were produced, a 13% decline year-on-year.

DST-Ural factory manufactured 10 mini crawler skid steer loaders in the first half of 2024, whereas none were produced in the first half of 2023.

Since 2012, the Kameshkovsky mechanical plant in Vladimir Oblast has been producing metal structures for mini skid steer loaders for Kovrov Electromechanical Plant. Over the past four years, KaMZ has independently produced its own skid steer loaders. A total of 16 were produced in the first half of 2024, but no data was available for 2023.

UMG is Russia’s only manufacturer of telescopic boom forklift trucks.

Their production was initially carried out at the Eksmash factory in Tver, and later at the Bryansk Ordnance Factory. In the first half of 2024, a total of 68 forklift trucks were produced, compared to only 11 in the same period last year.

The production of crawler dozers has generally decreased.

According to data from ASM-Holding, the Cheboksary Promtractor factory produced a total of 248 bulldozers in the first half of 2024, an 8% decrease year-on-year. However, Chetra’s comments about the production situation indicated a 25% increase in sales (which source to believe?).

Production at the DST-Ural factory has also slowed down. In the first half of 2024, a total of 123 bulldozers were produced, which is a 15% decrease compared to the previous year.

Now controlled by Tractor Plants company, the PC ChTZ factory produced 60 bulldozers in the first half of 2024, almost double the output of the same period last year.

The smaller enterprise, Chelyabinsk Industrial Tractor Plant, assembled only 5 bulldozers in the first half of 2024, down from 8 in the same period last year.

The new entrant in the bulldozer market, ELAZ, has temporarily ceased production of this type of equipment. Reference data: last year, only one bulldozer was assembled.

The production of pipe-laying machines has seen a significant decline.

The Promtractor factory only produced 16 units in the first half of 2024, a 78% drop; the DST-Ural factory produced 2 units, a decrease of 96%. It is worth noting that this market is basically dominated by a single major customer — the Russian natural gas company.

The production of graders also showed an overall negative growth.

The only large manufacturer, UMG company’s Bryansk Ordnance Factory and ChSDM plant, the former halved its output compared to the same period last year, with only 130 units produced in the first half of 2024; the latter decreased by 66%, producing only 8 units.

Here is the production situation of some smaller enterprises: the Road Machinery Plant produced 8 units (an increase of 100%); the St. Petersburg Tractor Plant produced 1 unit, maintaining the previous year’s level; ELAZ produced 2 units (an 80% decrease); SpetsDorMash produced 14 units (an increase of 1 unit); Selenga Heavy Machinery Plant produced 1 unit, the same as last year.

The production of road rollers was slightly better.

The Road Machinery Plant produced 134 rollers in the first half of 2024, a 4% increase over the same period last year. The Raskat plant produced 26 rollers, down by one unit from the first half of 2023.

The production of concrete mixers has seen a significant decline.

This is not hard to understand, as the main chassis supplier, KAMAZ, is currently filled with government orders. Data shows that the TuiMaz concrete mixer factory produced 375 concrete mixers, a 47% decrease over the same period last year; KOMZ-Export produced only 68 units, a decrease of 37%.

It is evident that the Russian engineering machinery manufacturing industry faced stern challenges in the first half of 2024, with some segments even facing production stagnation and significant market share declines. While some manufacturers have taken up new cooperation models or diversified production strategies, the overall situation nevertheless remains bleak.

Keywords: