Disclaimer: The following article was originally published by Cehome.

Source: https://www.cehome.com/news/20241021/317704_photo.shtml

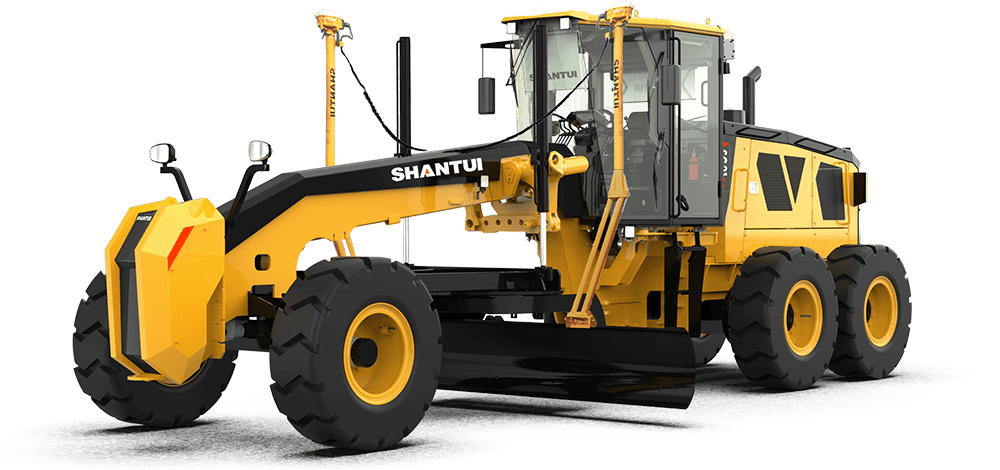

On October 21, 2024, at 14:06, under the column of Power and Transmission Technologies, PT Services, with Responsible Editor Ren Li and the author drew attention to a poignant issue concerning China’s construction machinery industry. As the world’s largest single market for construction machinery, China grasps the focused gaze of global industry leaders. Despite various factors leading to a slump in recent years, the robust market remains competitive, with giants from abroad and homegrown brands such as XCMG, Zoomlion, and SANY growing to compete head-on with world players like Caterpillar and Komatsu.

Beneath the surface of prosperity, however, a flaw persists in the competitiveness of high-end hydraulic components of domestic brands, which are either insufficient or non-existent.

Let’s now look at the ten top hydraulic brands globally:

- Bosch Rexroth: As a shining example of Germany’s Industry 4.0, Bosch Rexroth has earned global trust with comprehensive hydraulic solutions and exceptional service quality, dominating in automation control, mobile applications, and industrial drives.

- Parker Hannifin: With a century of deep technological accumulation, the American company Parker Hannifin excels in hydraulics, pneumatics, and fluid power across a wide range of solutions, from basic components to complex systems.

- Eaton: Known for efficient hydraulic systems and filtration technologies, Eaton commits to providing innovative, sustainable energy solutions worldwide, prevalent in aerospace, automotive, and heavy-duty trucks.

- Kawasaki Heavy Industries: As a Japanese industrial giant, Kawasaki excels in hydraulics and robotics. Its products are employed in construction machinery, injection molding machines, and ships.

- Danfoss: The Danish company is renowned for innovative technologies in refrigeration, heating, drive control, and hydraulics, favored for their efficiency, energy conservation, and environmental friendliness.

- Atos: The Italian manufacturer specializes in hydraulic components and systems, offering high-performance solutions for industrial automation and mobile machinery.

- Bucher Hydraulics: Known for precision hydraulics, the Swiss company stands out, especially in agricultural and food processing machinery.

- Yuken: A Japanese leader in hydraulic control technology, Yuken’s products are used widely in machine tools, injection molding machines, and construction machinery.

- Sauer-Danfoss: As a subsidiary of Danfoss, Sauer-Danfoss focuses on developing and manufacturing mobile hydraulic systems, providing efficient hydraulic power for vehicles, trucks, and construction machinery.

With the foreign brands leading the top nine, Hengli Hydraulics, a fast-growing domestic brand, sits at number ten.

Hengli Hydraulics has achieved commendable success in technology innovation and market expansion, proudly representing China in the hydraulic industry.

Despite these achievements, there remains a significant gap in core and high-end components, such as the CVT gearbox’s hydrostatic unit in construction machinery, currently supplied solely by Bosch Rexroth.

The 2011 earthquake in Japan, known as the 3/11 disaster, though occurring on Japanese soil, painfully exposed the short supply of core hydraulic components to China’s booming market.

China is rising at an astonishing pace to become a pillar of global manufacturing. From excavators and loaders to cranes, Chinese-made machinery spans the globe, showcasing the formidable might of China’s manufacturing. However, lurking behind these triumphs is a critical pain point — the reliance on and absence of high-end hydraulic components — a malaise for China’s construction machinery sector and a bottleneck hindering its advancement.

- High-End Hydraulic Parts: The “Heart” and “Soul” of Construction Machinery

Hydraulic parts determine the machine’s efficiency, stability, and longevity. High-end components, characterized by precision, reliability, and durability, are markers of a machinery’s technological prowess.

China’s industry has long been dependent on imports, particularly from Germany and Japan, whose advanced technology and quality have been favored by domestic manufacturers.

- The Pain of China’s Construction Machinery: The Stranglehold of High-End Hydraulic Parts

Technological barriers: High-end hydraulics involve material science, precision manufacturing, and fluid dynamics. Foreign firms’ technological fortresses, built over extended periods, are hard for domestic companies to breach in the short term.

Incomplete supply chains: A complete industrial chain is necessary for the development and production of high-end hydraulics, something China still lacks, leading to high costs and quality instability.

Misconceptions in market cognition: Some domestic companies undervalue critical components like hydraulics, leading to insufficient R&D investment and weak branding.

Complex international trade environment: Uncertain factors such as tariff adjustments and trade barriers aggravate supply chain risks for domestic companies.

- Breaking Through: From Catching Up to Running Alongside and Leading

China’s industry is actively seeking to shift from following to running alongside and even leading. While domestic brands like Weichai acquire German hydraulics like Linde, and Hengli Hydraulics represents domestic hydraulic power, the gap with global leaders is still stark.

Bridging this gap requires increased R&D investment and overcoming technological challenges, government and business cooperation, and embracing academia to solve critical issues. Strengthening exchanges with international entities and innovating upon absorbed technologies will enhance self-innovation abilities.

Improving the supply chain, strengthening brand building, and enhancing market cognition will reduce supply chain risks and promote domestic alternatives. Coupled with policy guidance and market incentives, this will accelerate the substitution process and expand the international market presence.

- Conclusion: A Promising Future, The Rise of China’s Construction Machinery Industry

Despite severe challenges, China’s industry faces them with unprecedented determination. As technology advances and the industrial chain strengthens, rapid development awaits the Chinese high-end hydraulic sector. In the future, with the force of independent innovation, China’s industry will occupy a more significant role in the global market and contribute to the manufacturing power dream.

In this battle without gunfire, every participant propels the industry forward. Let us join hands and conquer the tough times to witness the glorious future of China’s construction machinery industry!

Keywords: